No-Drill Blinds in the USA: A Clean, Damage-Free Window Solution

Outline:

– What no-drill blinds are, and how their core mechanisms work

– Types, materials, and finishes suited to U.S. homes and rentals

– Measuring and installation methods for reliable, damage-free results

– Performance: privacy, light control, energy use, and real-world use cases

– Durability, maintenance, safety, and limitations to consider

– Cost ranges, value, and a practical buying checklist

– Summary for renters, homeowners, and anyone avoiding holes

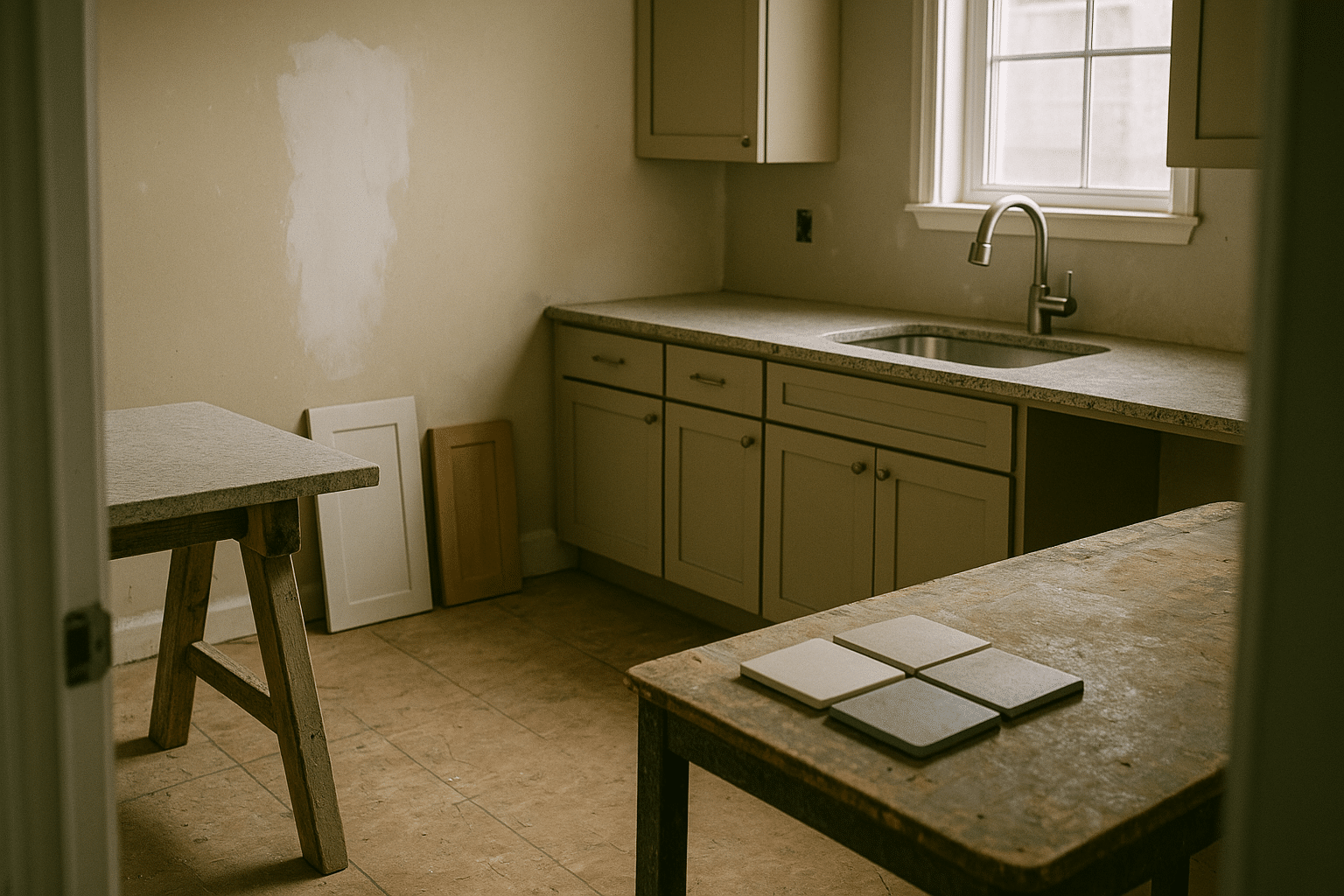

Understanding No-Drill Blinds: Types, Mechanisms, and Materials

No-drill blinds are window coverings designed to install without screws or holes. Instead of anchors and wall plugs, they rely on pressure, clips, magnets, or high-bond adhesive to stay put. The appeal is simple: a cleaner look, faster setup, and fewer repairs when moving out. For renters across the USA, that can mean protecting deposits; for homeowners, it avoids damage to fragile trim, tile, or metal doors. Because the term spans multiple designs, it helps to break the category into clear subtypes and see where each shines.

Common variants include:

– Tension-fit: A spring or compression bar presses a headrail between the jambs of an inside mount, similar to a shower rod. It avoids adhesives, works with sturdy frames, and removes cleanly. The key is a snug, square opening with enough depth to seat the rail.

– Adhesive-mount: A headrail or brackets bond to the frame or glass with industrial-grade tape. Good for smooth, clean surfaces like painted wood, vinyl, or aluminum. Surface prep and cure time matter more than force.

– Magnetic: Ideal for steel doors and sidelights. The headrail or brackets attach magnetically, enabling rapid removal for cleaning or seasonal swaps.

– Clip-on: Brackets hook over a window sash or frame lip, common with certain vinyl or metal assemblies. They prioritize reversibility but need compatible profiles.

Materials and finishes set performance and style:

– Aluminum slats: Slim, light, and moisture-tolerant; offer crisp tilt control and a modern profile.

– Faux wood slats: Heavier look with warmer tones; better in humid kitchens or baths than natural wood.

– Fabric rollers: Minimalist footprint; available in light-filtering, room-darkening, and blackout variants.

– Cellular (honeycomb) fabrics: Trapped air pockets add insulation and soften acoustics; their light weight pairs well with non-drill mounts.

Pros include quick installation, reversible setups, and versatility for rentals, dorms, historic homes, and offices. Limitations revolve around load and surface suitability. Adhesives can struggle on textured paint, dusty surfaces, or flaking finishes; tension-fit rails need square openings and sufficient friction. Expect the strongest results when surfaces are smooth, clean, and within the product’s weight and size limits. With realistic expectations, no-drill blinds deliver reliable light control without compromising your trim.

Measuring, Fit, and Installation: Step-by-Step Without Holes

Accurate measuring makes a no-drill install feel solid from day one. Start by deciding on an inside or surface mount. Inside mounts typically look cleaner and reduce light gaps when the frame is square; surface mounts (on-frame or on-glass, depending on design) may better handle shallow depths or irregular openings. In the USA, many residential windows include multiple panes and trims, so note protrusions, locks, and handles that could interfere with headrails.

Measuring checklist:

– Width: Measure inside the frame at top, middle, and bottom; use the smallest figure. For tension-fit, allow the manufacturer’s recommended compression clearance; for adhesive rails, keep alignment straight to minimize light gaps.

– Height: Measure left and right sides; use the larger figure to ensure full coverage. Add a small allowance for bottom clearance if a sill rises.

– Depth: Confirm the minimum depth for your chosen design so slats or fabric clear handles and tilt latches.

Surface prep is the unsung hero. Remove dust with a dry cloth, then wipe bonding areas with isopropyl alcohol and let them dry. Oils, cleaners with residue, or humidity can weaken adhesive grip. For adhesive systems, dry-fit the rail before peeling liners, mark light guide lines, and apply firm, even pressure for 30–60 seconds. Many tapes reach functional strength immediately but continue curing for 24–72 hours; avoid pulling loads during that window. Tension-fit rails benefit from careful leveling and incremental pressure: place, align, extend pressure modestly, and test. If your opening is slightly out-of-square, shim with thin, inconspicuous pads rather than over-forcing the rail.

Useful precautions:

– Avoid mounting over flaking paint; the tape may lift it during removal.

– Do not exceed recommended width/weight; heavier faux-wood slats may be too demanding for weaker adhesives.

– In baths or kitchens, allow surfaces to fully dry after showers or cooking, as steam can reduce initial adhesion.

– For magnetic setups, wipe rust-prone steel and consider a thin protective film if corrosion is a concern.

When done, cycle the blind several times. Look for racking, sagging, or shifting. Minor adjustments early pay dividends; once adhesives cure, repositioning becomes harder. Thoughtful measuring and patient prep turn a no-drill install into a confident, durable fit.

Performance and Use Cases: Privacy, Light, and Energy Considerations

No-drill does not have to mean no-performance. For privacy, slatted aluminum or faux-wood blinds allow granular tilt control, shielding interiors while admitting daylight. Fabric rollers and cellular shades create broader light transitions: light-filtering fabrics soften glare for workdays; room-darkening helps bedrooms; blackout is a sleep ally for shift workers. The closer the headrail sits to the frame, the fewer light leaks at the edges, especially with inside mounts.

Energy and comfort benefits depend on material and fit. Cellular fabrics add insulating pockets that reduce heat transfer through glazing, which can support more stable room temperatures across seasons. Even simple rollers can block direct solar gain during summer afternoons, reducing cooling load. In cooler months, snug-fitting coverings help limit drafts from older single-pane frames. While exact savings vary by climate zone and window type, tighter fits, reflective backings, and consistent use during peak hours strengthen results.

Where no-drill solutions excel:

– Rentals and leases: Avoid fees for patched trim or masonry. Move-out is easier, and windows return to original condition.

– Historic homes: Preserve old wood casings and avoid drilling fragile plaster. Reversibility respects architectural integrity.

– Glass doors and sidelights: Magnetic and adhesive mounts handle narrow frames without drilling into steel or fiberglass skins.

– Dorms, temporary offices, and short-term rentals: Speedy setup and takedown fit flexible living.

– RVs and small spaces: Lightweight, compact profiles with quick removal for travel or cleaning.

Consider potential trade-offs. Large, wide windows may challenge adhesive-only headrails unless specifically engineered for the span. In high-humidity baths, fabric selection matters; moisture-tolerant rollers or aluminum slats resist warping. Sound dampening is modest—cellular fabrics help more than slats, but window construction dominates acoustic performance. For bedrooms on street-facing elevations, pairing a light-filtering blind with a blackout overlay can balance daytime brightness and nighttime privacy without drilling.

Performance also includes how the blind feels day to day: smooth lift action, consistent tilt, and minimal shifting under gentle use. A no-drill system installed square and supported by suitable materials will stand up to routine adjustments, making your morning light feel intentional rather than improvised.

Durability, Maintenance, and Safety Over Time

Longevity comes from the interaction between material, environment, and use. Adhesive bonds tend to last longer on smooth, sealed surfaces that were properly cleaned before installation. Repeated high heat, heavy loads, or constant tugging can shorten life. In typical residential conditions, a well-prepped adhesive mount can serve for years; tension-fit rails can last even longer, provided springs or pads maintain pressure and surfaces remain clean.

Maintenance is straightforward:

– Dust weekly with a microfiber cloth or brush attachment to prevent buildup that adds weight and grit.

– For rollers and cellular fabrics, spot-clean with a lightly damp cloth; avoid saturating edges where adhesives or tension pads sit.

– For aluminum or faux wood, a mild soap solution removes kitchen film; dry promptly to maintain finishes.

– Inspect adhesive edges seasonally; if you notice lifting, gently press back after cleaning, or plan a controlled re-mount.

Removal should be deliberate. For adhesive rails, warm the area slightly with ambient room temperature, work dental floss behind the tape to slice through, and roll any residue off with fingertips or a citrus-based remover suitable for your surface. Go slow to avoid paint lift. Tension-fit rails release by relaxing the spring; protect trim with a soft pad as you ease pressure. Magnetic mounts simply detach; wipe both surfaces to prevent grit scratches when reattaching.

Safety deserves attention. Corded products can pose hazards to young children and pets; consider cordless or shielded-operator designs. Recent U.S. safety standards emphasize inaccessible cords on new window coverings, so verify compliance when shopping. Also check flame-spread ratings for fabrics near heat sources, avoid mounting where blinds could interfere with egress windows, and ensure brackets do not obstruct shutter hinges or tilt latches. In damp areas, promote airflow to discourage mildew; cellular fabrics, in particular, appreciate dryness to preserve their structure.

Expect natural wear: minor surface scratches on aluminum, slight fabric softening on rollers, and gradual pad compression on tension systems. None of these have to be deal-breakers. With modest care, most no-drill blinds will retain function and appearance long enough to make their convenience feel like a durable perk rather than a temporary hack.

Cost, Value, and How to Choose: A Practical Buying Checklist

No-drill blinds span an accessible price range in the USA, with costs varying by material, size, and special features. Typical ballparks per standard window (not oversized): basic vinyl or aluminum slatted styles often range from around $20–$60, faux wood from roughly $35–$90, fabric rollers from about $25–$70, and cellular options from approximately $40–$120. Add-ons like blackout backings, specialty widths, or custom trimming can nudge totals upward. Outfitting a two-bedroom rental with eight mid-size windows commonly lands in the few-hundred-dollar range, depending on style and quality tier.

Value shows up in saved time and avoided repairs. No patching spackled holes, no repainting around brackets, and fewer tools. For short leases, the ability to remove and reuse is meaningful. Even for homeowners, the benefit of preserving original trim—especially in older houses—can outweigh the slight premium some no-drill models carry. Think in terms of total project cost, including potential paint touch-ups or contractor fees that drilled hardware might trigger.

A practical checklist:

– Fit: Confirm inside width at three points, height at two, and frame depth. Check for locks, cranks, and handles.

– Surface: Prefer smooth, sealed, clean substrates. Avoid chalky paint or textured plaster for adhesive mounts.

– Mechanism: Choose tension for solid frames, adhesive for clean modern casings, magnetic for steel doors, and clip-on for compatible sashes.

– Material: Pick moisture-tolerant finishes for baths/kitchens, blackout or room-darkening for bedrooms, and cellular for added insulation.

– Operation: Favor cordless or shielded operators for safety and a cleaner look.

– Climate: In humid regions, prioritize materials that resist warping; in hot sun, consider reflective or darker fabrics based on glare goals.

– Removability: If you anticipate frequent moves, look for systems designed to release cleanly without residue.

Hidden costs and tips:

– Cutting to width can save money but requires careful, square trimming; when unsure, consider professional sizing.

– Wider spans may need center supports; some no-drill designs accommodate this, others do not—plan accordingly.

– For renters, photograph pre- and post-install conditions to document care taken with frames and paint.

– Low-VOC materials and odor-light adhesives improve indoor air quality during the first days after setup.

When you weigh price against installation ease, removability, and frame protection, no-drill blinds often emerge as a practical, well-regarded solution for modern living.

Conclusion: A Damage-Free Upgrade for Modern Living

No-drill blinds deliver a compelling blend of convenience, style, and respect for your walls. For renters, that means flexible light control without risking deposits; for owners, it preserves trim and speeds up projects. By matching the mechanism to your surface, measuring carefully, and choosing materials suited to your room’s moisture and light, you can enjoy privacy and comfort without a single hole. Consider them a tidy, renter-friendly path to better daylight—reversible, reliable, and ready for wherever you live next.