Learn about Kitchen Remodeling

Outline:

– Why Kitchen Remodeling Matters: Value, Function, and Everyday Comfort

– Budget, Scope, and Return: Making Numbers Work Without Compromise

– Layout and Ergonomics: From Work Triangle to Flexible Zones

– Materials, Finishes, and Systems: What to Choose and Why It Lasts

– Conclusion for Homeowners: From Plan to Punch List

Why Kitchen Remodeling Matters: Value, Function, and Everyday Comfort

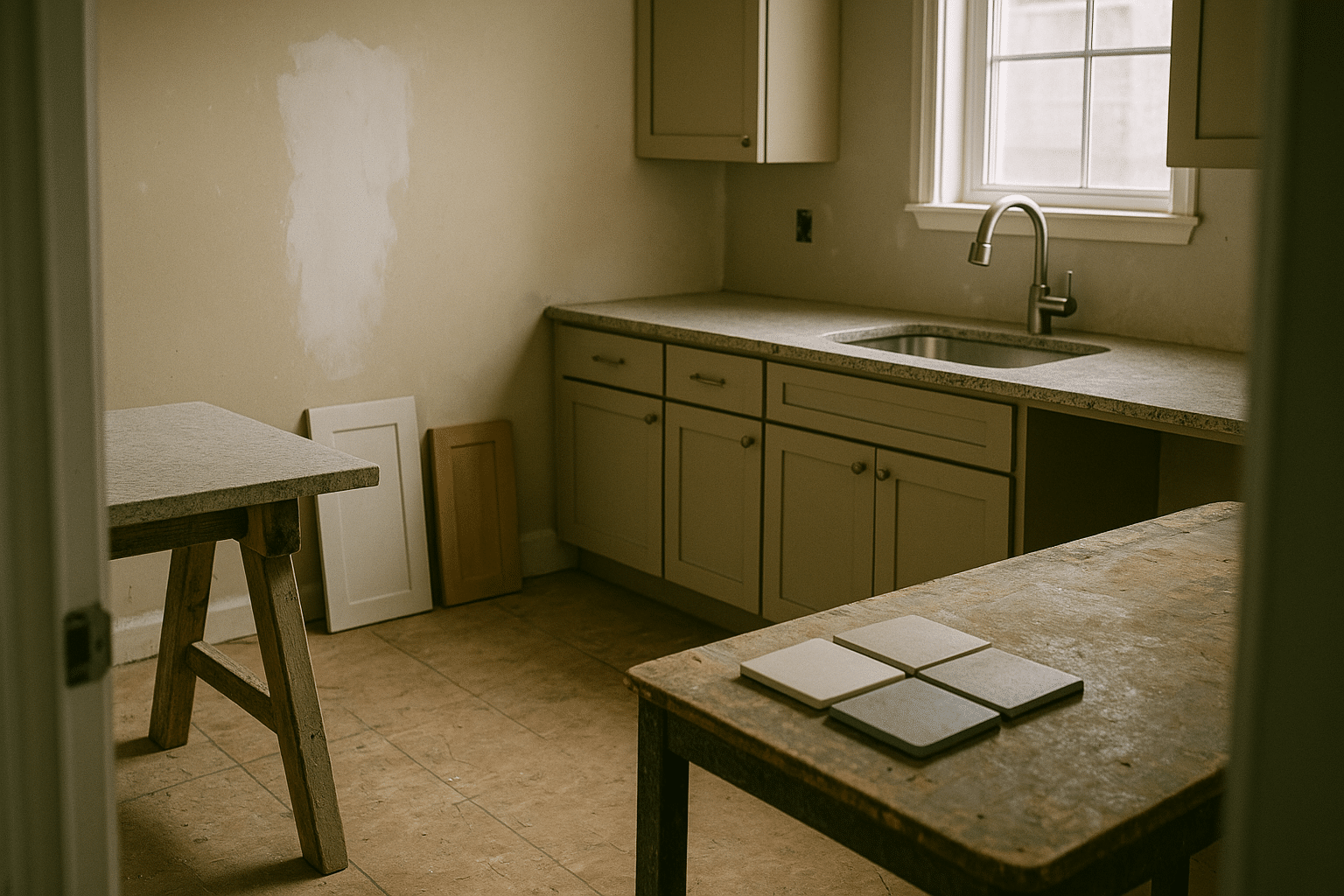

Remodeling a kitchen is less about chasing trends and more about aligning a hardworking space with the way you actually live. The kitchen handles cooking, conversations, homework, impromptu meetings, and morning routines—often all before lunch. A thoughtful refresh can improve safety, reduce wasted steps, and bring calm to daily tasks. From a financial angle, multiple industry reports consistently find that modest upgrades oriented toward function and durability tend to recoup a meaningful share of their cost at resale, while major overhauls can act as a long-term lifestyle investment.

Value comes from targeted improvements that solve clear problems. That might mean better task lighting to reduce eye strain, a layout that prevents traffic jams, or storage that keeps heavy items below shoulder level. Think of the remodel as a system: improve one part (say, ventilation) and you amplify the impact of others (less grease film means your finishes stay cleaner). Even if you never plan to sell, comfort and safety have tangible worth—quieter drawers, slip-resistant flooring, and a well-placed prep sink can make everyday cooking feel smoother and more enjoyable.

Consider a few practical reasons homeowners remodel kitchens today:

– Efficiency: smarter layouts reduce steps and cut meal prep time.

– Health: robust ventilation and easy-to-clean materials support air quality and hygiene.

– Accessibility: thoughtful heights, clearances, and hardware ease movement for all ages.

– Energy use: efficient equipment and better insulation trim utility costs over time.

– Resale appeal: neutral palettes and resilient materials stay attractive longer.

If your current space makes you work around bottlenecks, the remodel is an opportunity to flip that relationship—let the room work for you. Start by documenting pain points for two weeks. Where does clutter pile up? Which tasks feel awkward? This brief audit will guide priorities and help you set a clear scope, so the project delivers lasting value rather than a short-lived facelift.

Budget, Scope, and Return: Making Numbers Work Without Compromise

A transparent budget anchors every successful kitchen project. As a rough orientation, cosmetic refreshes (paint, hardware, lighting swaps, limited surface changes) often range from a few thousand dollars to the mid five figures, while midrange remodels with layout tweaks, new cabinets, and upgraded surfaces commonly span the tens of thousands. Full-gut, high-spec transformations can reach into six figures depending on size, structural changes, and custom details. Local labor rates and material availability can move these ranges substantially, so align estimates with your region and home type.

To allocate funds wisely, break the budget into predictable buckets:

– Cabinets: about 25–35% (larger if custom).

– Labor and installation: roughly 20–35% depending on scope.

– Appliances: about 10–20% (fewer dollars if reusing equipment).

– Countertops: about 5–15% depending on material.

– Flooring: approximately 5–10%.

– Electrical, plumbing, and ventilation updates: about 5–10%.

– Design, permits, and inspections: 5–10%.

– Contingency: 10–15% to manage surprises behind walls.

Return on investment varies by market and choices. Historically, restrained, functional remodels often see stronger cost recovery than extravagant projects, with many market summaries indicating minor kitchen updates may recoup a larger percentage than full luxury conversions. That said, return is not only about resale: fewer repairs, improved safety, and lower utility use contribute ongoing value. To enhance ROI, prioritize durable finishes, straightforward layouts, and timeless colors, then layer in character with easily replaced accents.

A few planning strategies keep costs in check without draining quality:

– Keep major plumbing and gas lines in place when feasible.

– Reface or repaint sturdy cabinet boxes instead of replacing them.

– Choose mid-grade, well-constructed materials where durability matters and save on less critical surfaces.

– Order key items early to avoid rush fees and delays.

– Use a milestone payment schedule tied to completed work, not calendar dates.

Finally, get at least three line-item quotes and compare scope apples to apples. Look for clear inclusions, realistic timelines, and warranties spelled out in writing. A budget built on honest assumptions will protect both your wallet and your schedule.

Layout and Ergonomics: From Work Triangle to Flexible Zones

Layout decisions determine how your kitchen moves with you. The classic “work triangle” (sink, cooktop, refrigerator) remains a helpful shorthand, with each leg ideally 4–9 feet and a combined total of roughly 13–26 feet. Yet modern households often benefit from zones—prep, cooking, baking, cleanup, coffee, and grab-and-go—to support multiple simultaneous tasks. Islands, peninsulas, and pantry walls become the anchors that balance flow and storage without forcing a single path through the room.

Clearances are foundational. Aim for at least 36 inches of aisle width for one cook and 42–48 inches where two people work side by side. Maintain 24 inches of landing space on one side of the sink, and ideally 15 inches on each side of the cooktop for hot pans. For refrigerators, leave about 12–18 inches of landing space on the handle side. Where wall ovens and dishwashers open, prevent door conflicts by offsetting adjacent cabinets or widening aisles.

Islands deserve special attention. Typical prep-friendly islands start around 36 by 60 inches, but the right footprint depends on room size and walking paths. Leave at least 42 inches of clearance on working sides; if seating is planned, allow about 24 inches of width per stool and a 12-inch overhang for knees. Keep trash and compost pull-outs near the main prep area, and place a secondary prep sink if you frequently cook with a partner.

Storage can make or break ergonomics:

– Put daily items between knee and shoulder height to reduce strain.

– Use deep drawers for pots and pans rather than low cabinets.

– Reserve high shelves for lightweight, seldom-used pieces.

– Add vertical dividers for baking sheets and cutting boards.

– Place spices and utensils near the cooking zone, not across the room.

Lighting and acoustics also shape comfort. Combine ambient ceiling fixtures with task lighting under wall cabinets and focused pendants above islands. Softer surfaces like cork, wood, or large woven rugs (away from sinks and stoves) can mute sound in echo-prone rooms. Thoughtful layout choices turn the kitchen into a quiet collaborator, letting you glide from prep to plate without detours.

Materials, Finishes, and Systems: What to Choose and Why It Lasts

Materials define texture, maintenance, and lifespan. Cabinet construction ranges from particleboard to plywood and composite options, with sturdy joinery and high-quality hardware doing the heavy lifting over time. Frameless styles maximize interior space; face-frame designs may offer a classic look and robust door mounting. Door finishes can be painted, stained wood, laminate, or thermoformed surfaces, each with distinct maintenance needs and resistance to humidity and heat.

Countertops require an honest look at habits. Engineered stone is dense and consistent, resisting stains with minimal sealing. Natural stone offers unique veining and high heat tolerance but may need periodic sealing and mindful cleanup. Solid surface enables seamless integration with sinks and coved backsplashes. Butcher block brings warmth and can be renewed with sanding and oil, though it prefers routine care and protection from standing water. Porcelain slabs and large-format sintered materials provide thin profiles, strong scratch resistance, and heat tolerance, often with minimal upkeep.

Flooring options each carry trade-offs:

– Porcelain or ceramic tile: durable, water-tough, cool underfoot; grout sealing and strategic rugs help.

– Luxury vinyl plank or tile: resilient, water-resistant, softer feel; check thickness and wear layer for longevity.

– Site-finished or engineered wood: warm and refinishable; protect from moisture and use mats near sinks.

– Cork: quiet, cushioned, and renewable; requires proper sealing in wet zones.

Behind the finishes, systems determine everyday quality. A properly sized range hood keeps air clear; a common rule of thumb is roughly 1 CFM of ventilation per 100 BTU of gas burner output, or 150–300 CFM for many electric cooktops. Ducted hoods that vent outside move grease and moisture away from the home; short, smooth ducts improve performance. Electrical updates often include dedicated circuits for high-demand appliances and code-compliant safety devices near water. For plumbing, evaluate shut-off valves, consider a deeper sink for splash control, and explore water-saving faucets with responsive flow controls.

Lighting quality matters as much as quantity. Mix ambient, task, and accent layers, aiming for a neutral color temperature around 3000–3500K in many homes and a high color rendering index (around 90 or above) for natural-looking food and finishes. Dimmers offer flexibility throughout the day. The right combination of honest materials and tuned systems creates a kitchen that wears in, not out.

Conclusion for Homeowners: From Plan to Punch List

Execution turns plans into a finished room. Expect a rhythm: design and selections, ordering, prep and protection, demolition, rough-in work, inspections, drywall and flooring, cabinet and counter installation, finish trades, and punch list. Lead times can surprise—some cabinets take several weeks, specialty counters may need multiple site visits, and appliances can require precise cutout dimensions. A schedule that sequences trades and respects curing and inspection windows avoids costly redo work and keeps momentum steady.

Here is a practical, high-level timeline to calibrate expectations:

– Design and permit preparation: 2–6 weeks, depending on complexity.

– Ordering and lead times: 4–10 weeks for cabinets and some finishes.

– Demolition and rough-in (plumbing, electrical, ventilation): 1–2 weeks.

– Walls, floors, and surfaces: 1–3 weeks including drying and inspection periods.

– Cabinet, counter, and appliance installation: 1–2 weeks.

– Finish work, adjustments, and punch list: 1–2 weeks.

Choosing the right team pays off. General contractors coordinate trades and handle permits, while a designer can prevent layout mistakes and ensure selections align. DIY can be effective for painting, hardware, and simple installs; licensed professionals should tackle structural changes, electrical, gas, and complex plumbing. For risk control, keep a 10–20% contingency, verify insurance and licenses, and use written change orders that list cost and time impact.

As you wrap up, walk the space with a detailed punch list: adjust doors and drawers, verify appliance operation, test GFCI protections, confirm ventilation, seal counters as needed, and inspect caulk lines. Request care instructions for each material and create a maintenance calendar for filters, sealants, and finish touch-ups. A calm, well-documented closeout protects your investment and sets a predictable routine for care.

In summary, a kitchen remodel succeeds when it matches your daily patterns, respects your budget, and prioritizes durable materials and safe systems. Start with a clear problem list, translate it into a scope, and let numbers, not impulses, guide choices. With a realistic schedule, thoughtful layout, and steady communication, you can create a welcoming, efficient room that supports cooking, gathering, and living—quietly and reliably—for years to come.