Essential Tips for Choosing Quality Preowned Cabinets

Outline and Roadmap for Preowned Cabinets

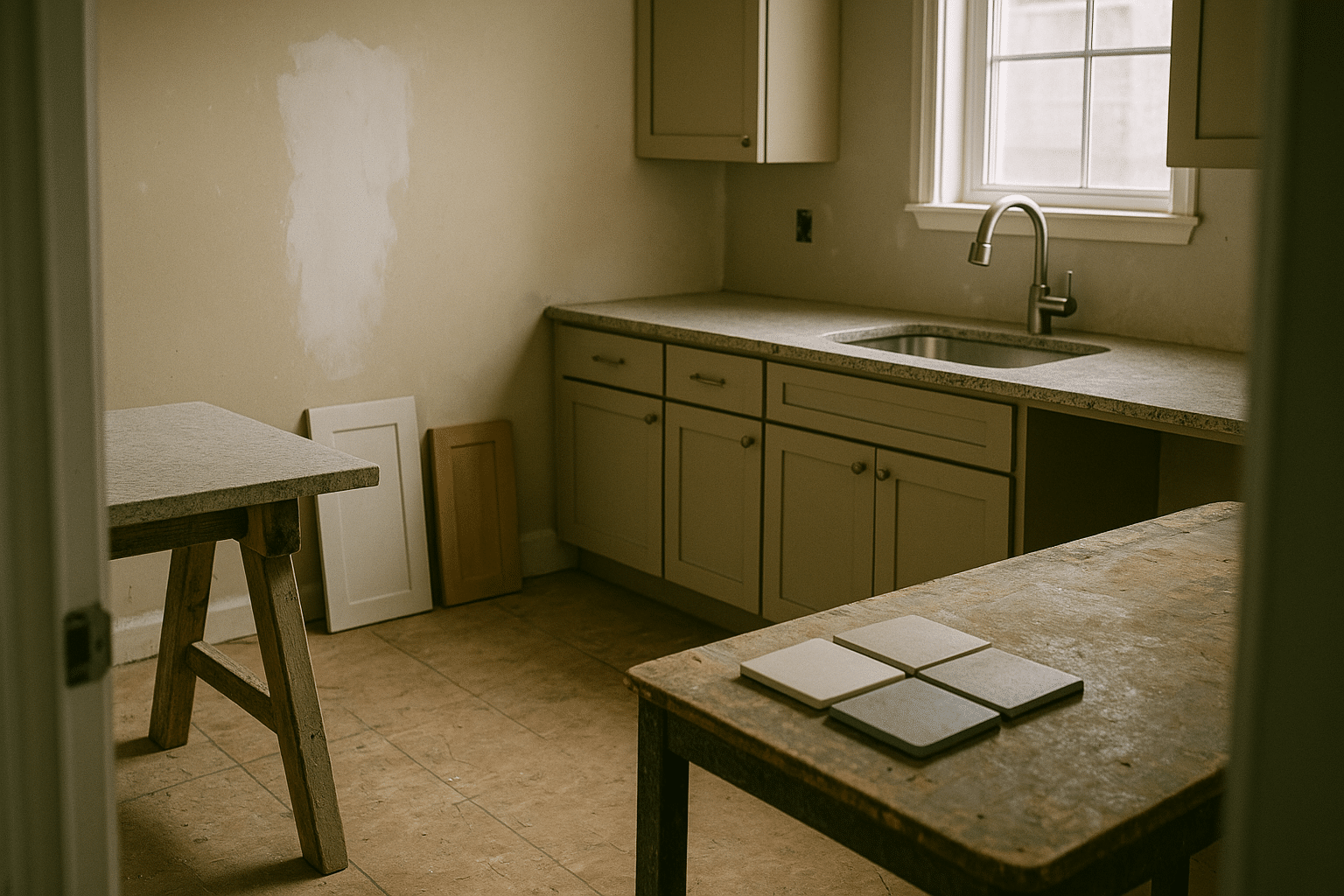

Preowned cabinets are the hidden gems of home improvement: they combine solid build quality, lower costs, and environmental benefits in one savvy decision. To help you navigate the process, this article begins with a clear roadmap and then dives deep into practical steps. Consider this your field guide for finding, inspecting, adapting, and installing cabinets that have already lived one useful life—and can thrive in yours. Whether you’re planning a complete kitchen overhaul or a utility-room upgrade, you’ll find methods to cut waste and keep standards high without sacrificing style or function.

Here’s the journey we’ll take together:

– Section 1 (you’re here): The outline and how to use it effectively. You’ll preview the structure and learn how each part supports smarter purchasing and smoother installation.

– Section 2: The “why” behind preowned cabinets—cost, quality, and sustainability—plus what advantages matter most for homeowners, landlords, and DIY renovators.

– Section 3: Sourcing and selection strategies. We’ll examine where to find viable sets, how to recognize durable materials, and how to match styles to your space.

– Section 4: A rigorous inspection and measurement playbook, including checklists for structural integrity, wear patterns, and layout fit.

– Section 5: Refurbishing, modifying, and installing. You’ll learn cleaning, finishing, and fitting techniques, then get a closing strategy to move from idea to action.

Use this outline as a checklist before you spend a dollar or lift a pry bar. Set a realistic target for your layout, style, and finish, then use the coming sections to confirm whether a given set can meet those goals. As you read, note questions in three categories: selection (Is this set sturdy and complete?), compatibility (Will it fit and work with my appliances?), and refresh potential (Can it be cleaned, painted, or refaced to meet my standards?). Treat your shopping trips like treasure hunts: arrive with measurements, a tape and square, a flashlight, and patience. The right preowned cabinets reward careful planning with standout value and satisfying results.

Why Preowned Cabinets Make Sense: Cost, Quality, and Sustainability

Many households pursue preowned cabinets because the numbers are compelling. New cabinet packages can consume a significant share of a renovation budget, especially when custom sizes or premium finishes enter the picture. By contrast, preowned sets commonly sell for a fraction of comparable new cabinetry, especially when purchased as a complete suite after a kitchen remodel. This price difference can free funds for upgraded countertops, efficient appliances, lighting, or professional installation—investments that boost day-to-day usability. Equally important, the shorter lead time of preowned cabinets helps you dodge manufacturing queues and delivery delays, which can otherwise stall a project for weeks.

Quality is another strong motivator. Many older cabinet sets were built with robust joinery, thicker veneers, solid-wood face frames, and plywood boxes that handle fasteners and moisture fluctuations better than light-duty alternatives. Drawers with dovetail joints and solid maple or oak sides often outlast stapled particleboard versions. Hinges and slides may be older but upgradeable; swapping in newer soft-close hardware is usually straightforward if the boxes are sound. Styles range from classic shaker and raised-panel to minimalist slab fronts, and the neutral lines of many traditional designs adapt well to modern finishes.

Reusing cabinets also carries tangible environmental benefits. Repurposing a solid set prevents thousands of cubic inches of bulky material from becoming waste and reduces demand for new resources. Transporting a local secondhand suite typically creates fewer delivery miles than ordering new inventory from distant factories. On top of that, reusing durable goods respects the embodied energy already invested in milling, drying, machining, and finishing the wood. While precise savings vary, the logic is simple: when a cabinet still has decades of structural life, extending its service is both practical and resource-smart.

Key advantages at a glance:

– Lower acquisition cost, freeing budget for other upgrades.

– Proven materials and joinery that can accept refinishing and hardware updates.

– Faster timelines with fewer supply-chain surprises.

– Reduced waste and resource consumption via reuse.

Where to Source and How to Choose: Materials, Styles, and Fit

Finding reliable preowned cabinets begins with widening your search and setting clear criteria. Local reuse centers, architectural salvage yards, custom shop leftovers, contractor auctions, online classifieds, and neighborhood renovation groups frequently list full sets removed during remodels. The most economical path is to purchase an entire matching suite at once—uppers, bases, and, if you’re fortunate, tall pantry cabinets and trim—because mismatched acquisitions quickly create style and height inconsistencies. If you’re mixing sources, prioritize consistent construction (e.g., all face-frame or all frameless) and compatible door styles to avoid visual dissonance.

Material selection drives longevity and refinishing results. Plywood cabinet boxes generally resist sagging and handle screws better than lightweight particleboard. Solid-wood face frames and real-wood doors refinish more easily than thin laminates. Medium-density fiberboard (MDF) can paint smoothly but dislikes repeated moisture exposure. Check drawer boxes: solid-wood sides with dovetails signal durable construction; thin stapled sides signal caution. Hardware matters, too: if hinge cups are the common 35 mm size and drawer slides mount to standard patterns, upgrades are simpler.

Style decisions should reflect both your space and your appetite for refinishing. Classic shaker or simple slab fronts adapt readily to paint, stain, or two-tone schemes. Ornate profiles can look fresh with careful color choice, but deep grooves require more prep. For layout compatibility, note that base cabinets are commonly 24 inches deep and around 34.5 inches high before countertops, while wall cabinets are often 12 inches deep. Widths typically move in 3-inch increments, which helps you map layouts with fewer filler strips. If the set includes specialty pieces—lazy susans, tray dividers, pull-out bins—confirm they suit your cooking habits rather than just looking clever.

Quick sourcing checklist:

– Target full suites first; mixing styles is more labor intensive.

– Favor plywood boxes and solid-wood or sturdy MDF doors for repainting or refacing.

– Confirm construction type (face-frame vs. frameless) and stick with one system.

– Measure actual widths and heights; don’t rely on “standard” labels in listings.

– Plan for fillers, panels, and end treatments to achieve a built-in look.

Inspection and Measurement Playbook: Avoiding Surprises

Inspection is where value is either confirmed or questioned. Start with structure: lift each cabinet and press diagonally to check racking; boxes should feel rigid. Sight along shelves for sag, and confirm back panels are intact and firmly attached. Look closely at sink bases and toe kicks for water staining or swelling; delamination or crumbly edges suggest prolonged moisture. Check the top and bottom rails for cracks near screw holes; repeated removals can weaken mounting points. Open and close every door and drawer; grit or wobble can signal worn slides or loose hinges.

Hardware and joinery reveal how gracefully a set can be refreshed. Dovetail drawer joints are a plus; if you see staples and paper-thin bottoms, budget for reinforcing or replacement. Confirm slide types (side-mount or under-mount) and test a loaded feel by gently pressing as you pull. For doors, inspect hinge cups: standard 35 mm bores make replacements easier. Verify that face frames are square and that frameless edges are unchipped. Check for smoke, pet, or chemical odors; persistent smells can migrate through finish layers and require sealing with a shellac-based primer before painting.

Measurements protect you from layout headaches. Record the height of base boxes (often ~34.5 inches), toe-kick height, and depths. Wall cabinets at ~12 inches deep should leave adequate clearance for small appliances. Standard widths in 3-inch steps (e.g., 12, 15, 18 inches) guide planning, but don’t assume—measure every piece. If your room varies out of square, anticipate scribing end panels and adding filler strips near corners. Mark appliance spaces: leave manufacturer-recommended clearances for range, refrigerator, and dishwasher doors, and confirm that the sink base aligns with plumbing.

Bring a compact field kit:

– 25-foot tape measure, small level, and a reliable square.

– Flashlight and inspection mirror for dark interiors and behind backs.

– Notepad with your room dimensions, window locations, and appliance specs.

– A few screws and a driver to test bite in box sides (with seller permission).

– Painter’s tape to label components and note which parts form pairs.

Refresh, Modify, and Install: From Pickup to a Polished Kitchen

Once you’ve secured a solid set, the refresh process turns possibility into a finished room. Start with cleaning: remove doors and hardware, label everything, and degrease boxes and faces with a quality cleaner or a phosphate-based solution; rinse thoroughly. Scuff-sand glossy finishes, vacuum dust, and use a bonding primer that adheres to previously finished surfaces. Waterborne enamels and hybrid coatings level well and cure harder than basic wall paint; if you’re staining, test on the back of a door to gauge color and blotch control. For laminate doors, consider light scuffing plus an adhesion-promoting primer, or replace panels with new fronts for a crisp reset.

Small modifications make preowned sets fit like they were planned. Use filler strips and end panels for clean transitions to walls and appliances. Add a new toe-kick if originals are damaged, and scribe end panels to uneven floors or wavy plaster. Replace dated knobs and pulls with hardware that matches your finish plan, and consider soft-close hinges and slides where compatible. Inside boxes, add rollout trays, tray dividers, or vertical partitions to tailor storage. If you need to bridge small gaps, a modest open shelf or a pull-out broom closet can turn an odd space into a feature.

Installation rewards careful sequencing. Find the room’s high spot and level base cabinets from that reference, shimming as needed. Secure boxes to studs through sturdy rails, and clamp adjacent face frames before fastening for tight seams. Hang wall cabinets off a temporary ledger to support their weight as you screw them to studs and each other. Protect clearances around the range and dishwasher, and double-check that doors and drawers open without collisions. Before countertops arrive, confirm that bases are co-planar; long straightedges help identify proud corners or dips to correct ahead of templating.

Budget and next steps, in brief:

– Expect modest costs for cleaners, primer, paint or veneer, new hardware, fillers, and fasteners.

– Factor transportation and a few shop supplies into the total; rent moving blankets and straps to prevent damage.

– Build a weekend plan: day one clean and prep, day two prime and sand, day three paint and install hardware, following up as cure times require.

Conclusion for homeowners and DIY renovators: preowned cabinets reward patience, measurement discipline, and thoughtful finishing. By prioritizing sturdy construction and a compatible layout, you gain credible savings without settling for flimsy materials. Start with the room you use most, gather your field kit, and visit a couple of reliable sources; when the right set appears, you’ll recognize it—and you’ll know exactly how to make it yours.