Remanufactured Car Engines: A Guide

Outline:

1) What a Remanufactured Engine Really Means

2) The Value Case: Cost, Reliability, and Environmental Impact

3) How to Choose the Right Remanufactured Engine

4) Installation, Start-Up, and Break-In: Doing It Right

5) Owning the Journey: Maintenance, Longevity, and Final Takeaways

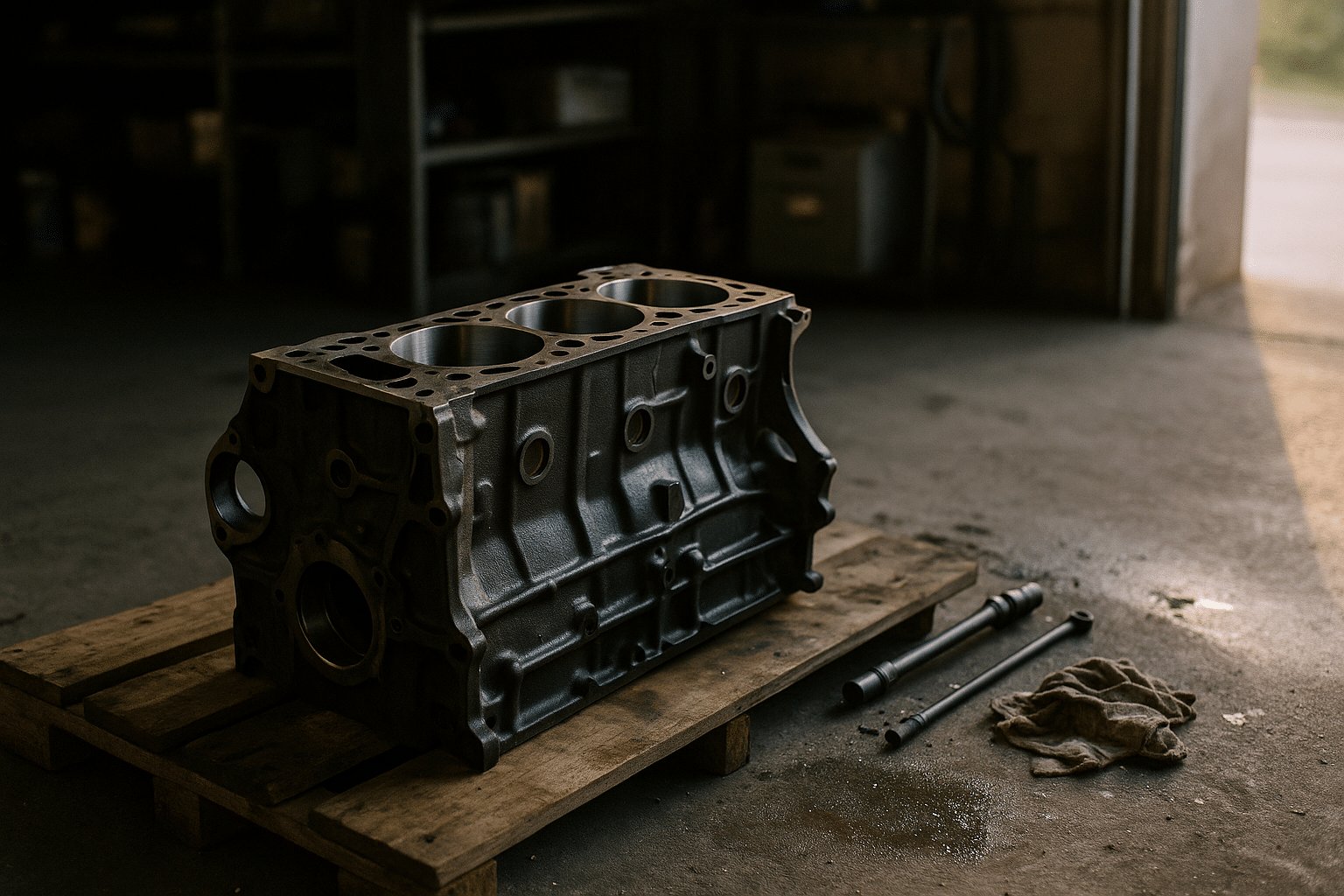

What a Remanufactured Engine Really Means

When people hear “remanufactured,” they often picture something halfway between used and new. In reality, a properly remanufactured engine is a carefully restored powerplant that has been completely disassembled, cleaned, inspected, machined where necessary, and reassembled with new wear components to meet or closely approach original factory specifications. The goal is consistency: repeatable clearances, standardized procedures, and test results that document performance. Where “used” means pulled from a donor with unknown history, and “rebuilt” can range from limited repair to partial refresh, “remanufactured” refers to a structured process guided by documented tolerances and quality checks.

At the heart of remanufacturing is measurement. Blocks are cleaned with hot tanks or aqueous systems to remove carbon and sludge, then checked for cracks using magnetic particle or dye penetrant methods. Cylinders are bored and honed to restore roundness and surface finish, typically to thousandths of an inch, with a crosshatch pattern that promotes proper ring seating. Crankshafts are measured for runout and journal size; if undersized, they are ground and polished to matched bearing dimensions. Heads are resurfaced to achieve flatness, valves are refaced, and guides replaced or honed to proper clearance. Key wear items are newly installed, including: – Pistons and rings – Main and rod bearings – Gaskets and seals – Timing components – Oil pump and frequently the water pump

Quality control is more than a checklist; it’s the feedback loop that keeps the process honest. Oil galleries are brushed and flushed to remove debris. Threaded holes are chased and repaired. Fasteners that are torque-to-yield are replaced. Clearances are verified with micrometers and plastigage, and rotating assemblies are balanced to reduce vibration and improve longevity. Before shipping, many suppliers run compression or leak-down tests, and some perform hot or cold test stands to verify oil pressure, vacuum, and smooth idle. The outcome is an engine that has not only been refreshed, but also documented. Compared with a gamble on an unknown used unit, remanufacturing is a methodical path toward reliable performance, supported by data and a uniform process.

The Value Case: Cost, Reliability, and Environmental Impact

Why would a driver or fleet choose a remanufactured engine over a brand-new crate or a low-mileage used takeout? The short answer is balance. Remanufactured engines often deliver a compelling mix of price, predictability, and sustainability. Upfront cost is typically lower than a new engine, frequently by 30–50% depending on model, labor rates, and regional availability. A used engine may be cheaper, but the value equation shifts once you consider hidden risks: undocumented service history, unknown oil change intervals, and possible damage from overheating or detonation. With remanufacturing, you pay for workmanship and measured tolerances rather than a roll of the dice.

Reliability is where remanufactured engines quietly shine. Fresh wear components, corrected machining, and updated parts (when applicable) reduce the chance of early failure. Many suppliers publish testing protocols, such as compression baselines or oil pressure metrics at hot idle and at a specified rpm. While exact warranties vary, coverage commonly spans significant time or mileage, giving owners reasonable peace of mind. The practical effect is smoother startups, consistent oil consumption, and fewer surprises. For those managing downtime—rideshare drivers, delivery services, tradespeople—predictability translates to revenue protection.

The environmental case is equally strong. Remanufacturing conserves energy and materials by reusing the core—the block, crankshaft, and heads—when they pass inspection. Industry studies have repeatedly noted that remanufacturing can save a substantial portion of the raw materials and energy compared with building new. That means fewer castings, reduced smelting and machining hours, and lower embodied carbon. Consider the lifecycle impact: – Material savings by reusing major castings – Reduced energy demand for machining and foundry work – Lower emissions associated with manufacturing and logistics For owners who want to extend vehicle life responsibly, a remanufactured engine is among the most resource-conscious options available, marrying performance with a lighter environmental footprint.

How to Choose the Right Remanufactured Engine

Selecting the right unit is part detective work, part research—get it right, and installation is straightforward; get it wrong, and you inherit fitment headaches. Start by confirming the exact engine code and build details from your vehicle identification. This includes displacement, induction type, and emissions family. Even within the same model year, running changes can alter sensors, timing configurations, or mounting provisions. Ask the supplier to confirm compatibility with your vehicle’s emissions calibration and fuel system architecture. A dependable sale includes documentation that ties the engine to your application beyond a generic label.

Quality signals matter. Look for clear statements about machining steps, parts replaced, and testing performed. Better documentation typically lists: – Cylinder bore sizes and finish targets – Crank journal measurements and bearing clearances – Head resurfacing specs and valve work – Compression or leak-down results – Oil pressure readings during test runs If a vendor can’t answer basic questions or provide a written process, consider it a red flag. It’s reasonable to ask for a sample build sheet or a template of the report you will receive. Warranty terms should be transparent, noting whether labor is covered, what triggers a claim, and what maintenance proof you must retain.

Core return policies also affect total cost. You’ll usually pay a core charge refunded once the old engine is returned complete and within a specified time. Study the fine print—damage from a catastrophic failure may reduce credit if major castings are unusable. Plan the logistics: palletizing, shipping windows, and any required plugs or caps to prevent fluid leaks. Before purchase, confirm accessory and sensor policies: some units ship long block only, while others include timing covers, oil pans, or injectors. Match what you have to what is supplied so your installer can schedule labor accurately. A short checklist can keep you on track: – Verify engine code and emissions family – Confirm long block vs. dressed configuration – Get machining and testing documentation – Understand warranty and labor coverage – Plan core return timing and shipping details

Installation, Start-Up, and Break-In: Doing It Right

A remanufactured engine can only be as good as the installation that brings it to life. Preparation begins before the hoist lifts anything: drain and flush the cooling system, inspect the radiator, and pressure-test for leaks. Replace components that can sabotage a new start, such as brittle hoses, cracked thermostats, or a clogged radiator. Fuel and ignition systems deserve the same scrutiny—dirty injectors and weak coils can lead to lean conditions and misfires. Oil coolers and lines should be cleaned or renewed so old debris doesn’t contaminate fresh bearings.

At install time, prime the oiling system. This can be as simple as pre-filling the oil filter, or as thorough as spinning the oil pump with a priming tool depending on design. Verify correct torque values and sequences for head bolts, main caps, and critical fasteners. Sealing surfaces demand attention: use recommended sealants sparingly, replace one-time-use fasteners, and ensure dowel alignment to prevent gasket shifts. Before first crank, conduct a checklist: – Verify all electrical connectors and grounds – Confirm coolant and oil levels – Check vacuum line routing – Ensure intake and exhaust gaskets are seated – Inspect for any pinched harnesses or hoses

Initial start-up is a moment to be methodical, not dramatic. Disable fuel or ignition and crank to build oil pressure, then re-enable and fire the engine. Watch gauges and scan live data: coolant temperature, oil pressure, fuel trims, and misfire counters. Address air pockets in the cooling system by following the bleed procedure. During the first 20–30 minutes, vary rpm gently to encourage ring seating and keep an ear tuned for abnormal noises. Break-in oil, if specified, should be used and changed early—often at 500–1,000 miles—followed by the recommended viscosity. Avoid extended idling and heavy loads until the second oil change. A disciplined approach pays dividends in ring seal, cam wear patterns, and overall longevity. In short, treat the first miles like a handshake with your engine’s future.

Owning the Journey: Maintenance, Longevity, and Final Takeaways

Once the odometer starts rolling again, ownership habits determine how far your remanufactured engine will carry you. Stick to scheduled oil changes and choose the viscosity and specification recommended for your application. Filters matter; quality filtration prevents abrasive wear that slowly erodes bearings and cylinders. Keep an eye on coolant health—pH and freeze protection affect corrosion and cavitation over the long term. Vacuum leaks, tired PCV systems, and clogged air filters can nudge fuel trims in the wrong direction, increasing heat and stress. A few simple practices help cement reliability: – Follow oil service intervals and use the specified grade – Maintain a clean, leak-free cooling system – Replace spark plugs and coils at suggested mileage – Monitor for codes and address small issues early – Keep records to preserve warranty and resale value

For budget planning, think in total cost of ownership rather than the install bill alone. A remanufactured engine often extends a vehicle’s useful life by years, deferring the expense of a replacement vehicle, increased insurance, and taxes. Consider a practical scenario: if an engine and installation cost less than several months of payments on a newer vehicle, the payback can be quick, especially for drivers logging steady miles. Fleets benefit too—predictable downtime, standardized units, and serviceable components reduce operational turbulence. Meanwhile, the sustainability angle is a quiet asset for businesses reporting on environmental metrics.

So, who stands to gain the most? Drivers who like their current vehicle but face a tired or damaged engine; DIY enthusiasts seeking a documented, repeatable foundation; and small businesses where uptime is non-negotiable. Choosing a remanufactured engine is not a gamble; it’s a disciplined decision supported by measurements, parts traceability, and testing. If you take the time to choose a well-regarded supplier, verify compatibility, and follow a careful install and break-in, you’re positioned for many dependable miles. In a world that often pushes “new” as the only answer, remanufacturing offers a different kind of upgrade—one that values craft, conservation, and the satisfaction of bringing a solid machine back to life.